Dear Readers,

In this week’s blog, we try to understand why we’re amid a Global Semiconductor Shortage. How these Shortages of semiconductors have been hurting manufacturers of automobiles, Laptops, and Consumer electronics; they are struggling to meet demand because they don’t have the semiconductors. Mobile phone companies have to pay through the roof to source critical parts.

Ambimat Electronics, with its experience of over four decades as an ODM of IoT products, wishes to draw the attention of its customers and readers of blog posts towards how a global semiconductor shortage is impacting multiple industries.

Introduction

The global chip shortage came as sudden news to many investors in industries that rely on the tiny, yet ubiquitous, electronic product.

The delay, which is affecting products from cars to smartphones, has been looming for some time. Playing a pivotal role has been a series of external forces, including trade restrictions, offshoring, and the global Covid-19 pandemic. Some companies will need to get used to the global chip drought. Pandemic-led demand swings and trade wars have left factories short of microprocessors.

High global demand amid a pandemic

When Covid-19 hit China, it caused the first wave of supply constraints. Factories shuttered to deal with the pandemic, producing a slowdown in manufacturing that would lead to a drop in items that would require chips. As the pandemic moved from China to across the world, the issue went from one of limited sales capacity for chip-dependent industries to one of potentially halted demand. This is where the deepest wounds of the shortage originated.

In the early days of the global pandemic, we saw unprecedented demand for PCs, cameras, keyboards, and displays. People who had PCs realized they needed better versions, and multi-person households could no longer share devices. This growing demand led to over 10% growth in the PC space for 2020, and surging demand in the fourth quarter reached 25.4%.

In itself, that caused a chip crunch as demand didn’t just peak for a short period to help people work and learn remotely, but the need stayed high with expectations that it would continue for at least a few more quarters.

Covid-19 didn’t only drive demand for PCs; it fundamentally changed our behavior. It halted going out to eat, attending a ballgame, or going to the movies. This behavioral shift moved dollars from venues to home entertainment. People in droves were buying smart TVs, streaming services, and gaming consoles. Like PCs, all of these are dependent on volumes of chips — and this demand wasn’t expected, and therefore wasn’t forecasted.

Tablets had their strongest demand since 2015, with over 160 million units sold in 2020. For Chromebooks, over 11 million units were sold versus less than 4 million a year earlier. Smart televisions flew out the door, up from less than 4 million units in the fourth quarter of 2019 to nearly 5 million units a year later.

Difficult to forecasts during uncertain times

Coupled with this demand came a complete miss from economists and demand planners across sectors.

The first was the mobile (smartphone) industry. With the rising demand for PCs early on in the pandemic came a narrative of stifled demand for smartphones. With all of us locked down at home, we were supposed to see material decreases in mobile devices’ demand. While forecasters were right in the early onset of the pandemic, it was business as usual for the smartphone industry by the third quarter.

Auto and electronics makers that cut back drastically in the early days of the outbreak are now rushing to re-up orders, In both cases, smartphone makers and automotive manufacturers heeded warnings of massive downtrends in demand. So they cut their semiconductor forecasts. And in a fabless world, where access to chips is entirely dependent on manufacturing facilities that handle the global demand for chips, those cuts led to gaping holes in supply.

By the fourth quarter, demand had surged to nearly pre-pandemic levels, down by only 2%, according to Canalys data. The 5G cycle, including the introduction of Apple’s 5G variant, further spurred demand.

Automakers began warning of a semiconductor shortage sometime late last year after demand for vehicles picked up in many parts of the world following a shutdown of production plants due to the pandemic. However, the production has not been able to shift back to the requirements of the auto segment as quickly.

Geopolitical factors

Geopolitical factors also played a role, specifically when the Trump administration began tightly regulating sales of semiconductors to Huawei Technologies, ZTE, and other Chinese firms. Those companies began stockpiling chips essential to 5G smartphones and other products. At the same time, American firms were cut off from chips made by China’s Semiconductor Manufacturing International Corporation after the federal government blacklisted the firm.

So when will the shortage be resolved?

Semiconductor factories – which are largely based in Asia – are in the process of ramping up production, but have warned that any increase will not be instant.

The chips are themselves incredibly complex examples of manufacturing and can take up to 26 weeks to produce. Building chip plants are expensive and will require sustained investment. Semiconductor fabs making the most advanced chips can take as long as three years to build and cost roughly $10 billion each,

Bottom Line — The semiconductor shortage is pulling multiple industries to its knees.

About Ambimat Electronics:

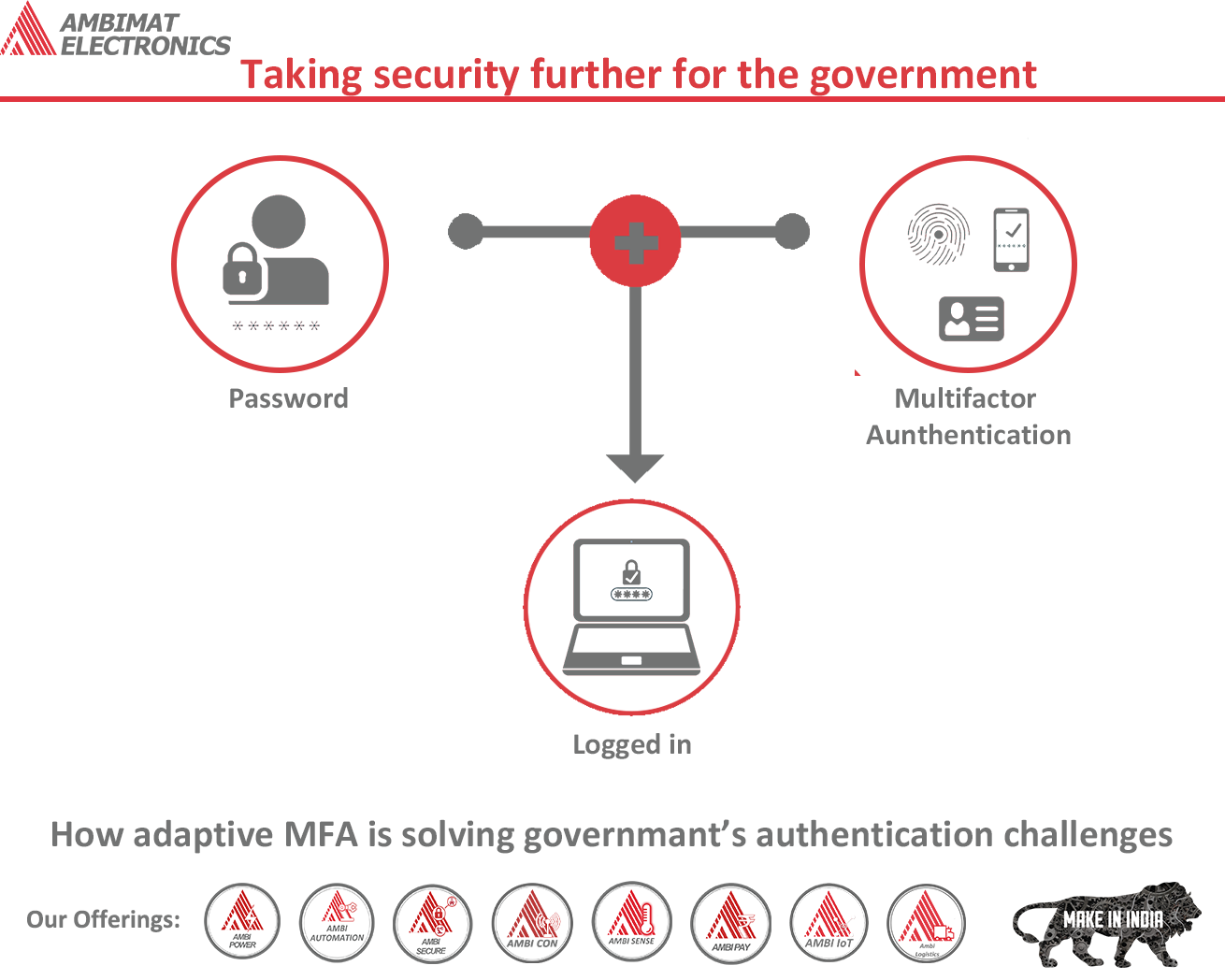

With design experience of close to 4 decades of excellence, world-class talent, and innovative breakthroughs, Ambimat Electronics is a single-stop solution enabler to Leading PSUs, private sector companies, and start-ups to deliver design capabilities and develop manufacturing capabilities in various industries and markets. AmbiIoT design services have helped develop Smartwatches, Smart homes, Medicals, Robotics, Retail, Pubs and brewery, Security.

Ambimat Electronics has come a long way to become one of India’s leading IoT(Internet of things) product designers and manufacturers today. We present below some of our solutions that can be implemented and parameterized according to specific business needs. AmbiPay, AmbiPower, AmbiCon, AmbiSecure, AmbiSense, AmbiAutomation.

To know more about us or what Ambimat does, we invite you to follow us on LinkedIn or visit our website.

Reference:-

https://www.livemint.com/technology/tech-news/semiconductor-shortage-leaves-u-s-lawmakers-seeking-elusive-fix-11613915490211.html

https://theacracy.com/global-chip-shortage-slows-down-big-industries/g

https://www.nytimes.com/2020/09/26/technology/trump-china-smic-blacklist.htmll

https://www.canalys.com/analysis/smartphone+analysis

https://www.msn.com/en-us/money/markets/this-is-how-the-great-chip-shortage-happened-e2-80-94-and-how-it-gets-solved/ar-BB1dL5qY

https://futurumresearch.com/research-reports/pc-industry-and-chips/