Dear Readers,

Today the world is picking up any solution that can help fight COVID-19 and unfortunately, this situation has given birth to rampant myths and misunderstandings against technologies that can save you and your loved ones against this pandemic.

As a company involved in the use of UV technology in products for over 35 years, we at Ambimat Electronics, feel it is our fiduciary responsibility towards society as a whole to clear such myths and to share our knowledge

Our take on the topic

In order to ensure safety, while reopening their establishments; businesses, entrepreneurs, founders, facilities managers, and support staff are considering procuring off-the-shelf available solutions to reduce the probability of being infected while this Global COVID 19 pandemic continues.

There are two primary criteria which determine the effectiveness of a solution

- Quality of the product and

- The method of use with the product.

Take sanitizers for example – medical grade sanitizers are recommended to have above 70% alcohol (indicating quality) and are used in a generous quantity that almost drenches your hands for a few seconds while you rub them (method of use).

Similarly, recommended guidelines with washing hands is to lather hands with soap for at least 20 seconds. But if used for less than 20 seconds, does the hand-washing become ineffective? Maybe to a certain degree but not completely.

What one intuitively realizes here is the categories of solutions like sanitizers, deep-cleaning disinfectants, and soap, can do limited harm if the quality of the product is not up to the mark and method of practice is not followed as prescribed. But there are certain off-the-shelf solutions where it causes more harm if the method of practice is strictly not followed.

One such solution gaining quick popularity is the UV-C (UltraViolet-C) based sanitization solutions. Artificially produced UV-C has become a standard method of sterilization – one used in hospitals, Banks, and homes/offices every day. UV-C emitting robots have been developed to disinfect floors in hospitals, Banks have been using UV-C based devices to disinfect monetary bills within the vault, and it’s presence in your homes/offices with the water filters that use UV-C to purify it.

One such product has been developed by the DRDO as well

Harmful effects of UVC

But on this flip side, this technology has the potential to do more harm than good, if due caution is not taken in the product design. Some of the potentially harmful effects are …

* Development of Skin Cancer with exposure to UV-C rays even in small quantities and even for just a few seconds

* Reduced immunity with direct exposure in the short term.

* Probability of vaccines, and other classes of medicines having reduced effectiveness on exposure.

Safe uses of UV-C

To maintain one’s own safety, it’s important to note that one should strictly avoid exposing food / edible stuff to UV-C and limit to only exposing inanimate materials/objects like metals, plastic, cloth, glass, cardboard, etc. e.g. One’s Keys, Spectacles, Trouser, Files, Cash (coins and notes alike), etc. for the purpose of sanitization.

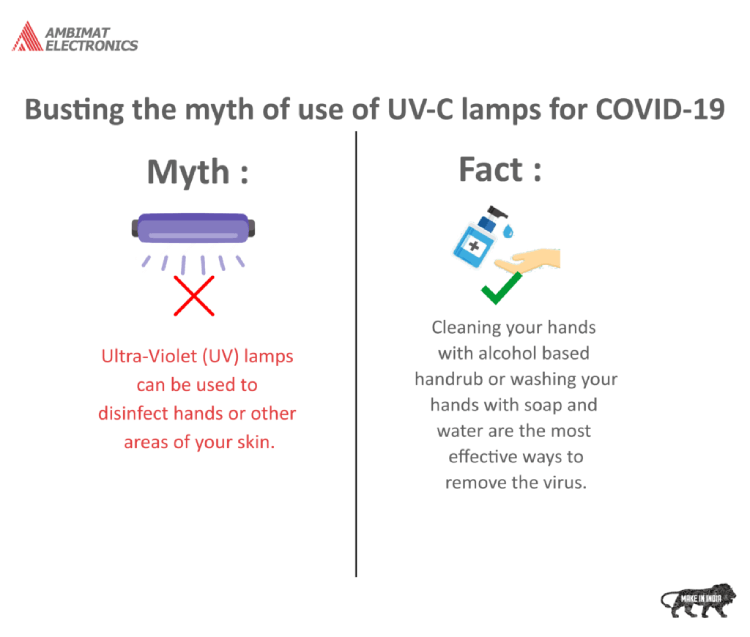

Due to these high risks of harmful effects of UV C, the World Health Organization (WHO) has issued a strong warning against people using UV-C light to sterilize their hands or any other part of their skin (see reference section).

The given list is only a subset but is a good indicator of how severe the harmful outcomes could be.

Use of automation for safety

While using UV-C to sterilize inanimate objects and to counter the probability of malfunction and increasing exposure to life-threatening situations, the UV-C solutions need to be custom designed with sufficient automation in place.

Incorporating simple automation in designing UV-C based gadgets can increase product effectiveness greatly while keeping humans safe and your business running without interruptions.

Steps for automation can include

* Self-monitoring isolation chambers which send you an app notification when they identify a leakage

* Automated timer or action-based triggers for switching on and off the UV C source.

* Introduction of automatic kill-switch, if accidental movement or action is detected in the area of disinfection.

* Controlled timing of UV-C exposure based on material and area of the object being disinfected and power being transmitted by the UV Source.

It is definitely advisable to select a product having relevant certifications and safety standards. Hence, if you are reopening your business and are considering putting in UV-C based solutions for large areas or niche applications, it is best to consult an expert for the required automation and monitoring that needs to be in place.

This investment in safety now will give you amplified returns over the next few months by reducing the probability of your business being affected while the pandemic continues.

About Ambimat Electronics:

With design experience of close to 4 decades of excellence, world-class talent, and innovative breakthroughs, Ambimat Electronics is a single-stop solution enabler to Leading PSUs, private sector companies, and start-ups to deliver design capabilities and develop manufacturing capabilities in various industries and markets. AmbiIoT design services have helped develop Smartwatches, Smart homes, Medicals, Robotics, Retail, Pubs and brewery, Security.

Ambimat Electronics has come a long way to become one of India’s leading IoT(Internet of things) product designers and manufacturers today. We present below some of our solutions that can be implemented and parameterized according to specific business needs. AmbiPay, AmbiPower, AmbiCon, AmbiSecure, AmbiSense, AmbiAutomation.

To know more about us or what Ambimat does, we invite you to follow us on LinkedIn or visit our website.

References

https://www.bbc.com/future/article/20200327-can-you-kill-coronavirus-with-uv-light

https://www.who.int/uv/en/