Challenge:

The challenge was to deliver a solution for monitoring the technicians’ productivity operating various industrial machines and to monitor overall productivity of the shop floor.

Approach/Solution:

To resolve this challenge, AmbiAutomation came up with an efficient and simple idea. We focused on the monitoring of machines by collecting the power consumption data and transferring it for further analytics.

The AmbiAutomation team customized one of their existing products to collect power consumption data from the Electric meters over MODBUS.

Transfer collected data to monitoring power consumption details along with time stamps.

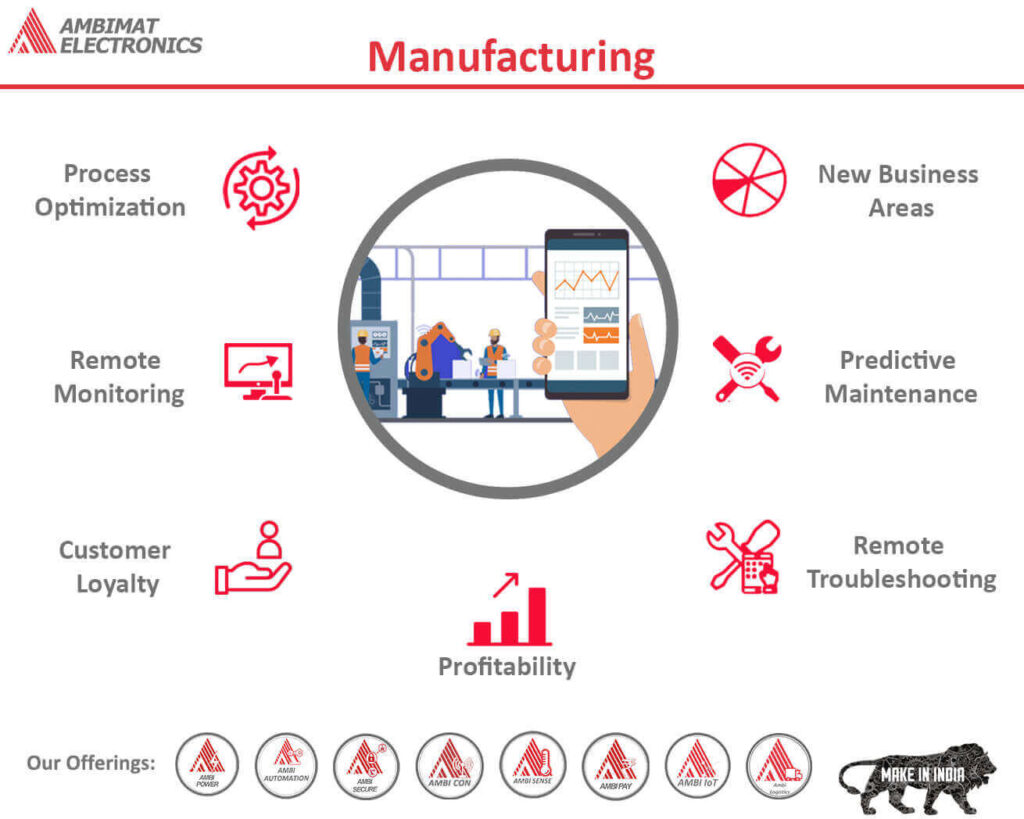

AmbiAutomation designed a solution in which data collected through power consumption monitoring of the machine enabled us to outline manufacturing data into real-time insights and benefits.

- Machine status – On/off, run rate, speed

- Downtime & Utilization – Planned/unplanned stops

- Operator effectiveness – Labor productivity and efficiency

- Energy – Electricity use

Along with that, several other features were offered to keep the management updated about the machine’s activity.

For example:

SMS alerts were sent to management when the machines were powered ON and powered OFF.

On-demand review of power consumption was also provided via an SMS as well as on a PCB via a Graphical User Interface.