Stage

CONCEPT/IDEATION

- You see a problem that you want to solve and list out ways to approach the solution.

- You find the target market, discuss solutions with them and zero in on the most appropriate solution.

- Develop the use cases of your product (your design team will need this).

Let us help you with your concept. Schedule a time to talk to us.

Stage

PROOF OF CONCEPT

- A proof of concept (POC) is evidence, which demonstrates that a design concept, or a business proposal, is feasible.

- This doesn’t need to look like a product and is commonly referred to as a breadboard model.

- You need to attempt to implement the maximum functionality possible.

- During this stage you will comprehend what is realisable and what is not. This stage will help you decide your MVP (Minimal Viable Product).

Let us help you with your POC. Schedule a time to talk to us.

Stage

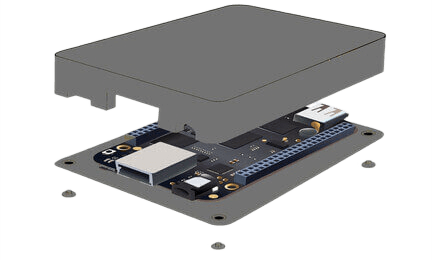

PROTOTYPE

- You are basically converting the design implemented for the proof of concept to a Printed Circuit Board (PCB).

- Here is when you almost finalise the look of the product, the size and shape of the PCB along the Bill of Material.

- During this stage you may also try to improve the performance of your proof of concept.

- Based on this stage you will get a better idea of the manufacturing costs of the product.

- The look of the product is finalised by an industrial design house and this stage goes hand in hand with prototyping.

Let us help you with your prototype. Schedule a time to talk to us.

Stage

INDUSTRIAL DESIGN

- These are the people who define how the world is going to see your product.

- They usually start with understanding the shape of your prototype (or at times define the shape of the PCB for you) then continue to design the contours.

- They also help you finalise any mechanical parts.

- The hardware design team and the industrial design team should work hand in hand to make sure your product looks the best that it can.

- Get some enclosures 3D printed to make sure your prototype fits well. The User Interface and the User experience are paramount for your product.

- Get feedback from your target user base.

Let us help you with your Industrial design. Schedule a time to talk to us.

Stage

TESTING

- Test your prototype thoroughly and spend enough time on it.

- Don’t have the same engineers building the product test it. (That’s the worst mistake)

- Take various use cases and test them in different environmental conditions like temperature, humidity, vibrations, extreme electrical input parameters, drop-tests, shocks, etc.

- Document your findings so that it helps in your next iteration/revision.

Let us help you with your testing. Schedule a time to talk to us.

Stage

Design for manufacturability

Your PCB and your 3D printed model work great with each other. But when you find out the costs for scaling up production you understand that the cost is very high. So your PCB as well as your mechanical designs need to go through a process called Design for manufacturability.- Examine the design to find out the ease of manufacturability index as well as the cost of manufacturability of each mechanical part.

- Redo the same for each electrical part after examining the cost of the bill of material of the PCB, the cost of the PCB itself etc.

- You may want to invest in making the mechanical mould at this stage.

Let us help you with your design for manufacturability. Schedule a time to talk to us.

Stage

CERTIFICATIONS

- CAUTION: Make sure you have tested your product thoroughly. You cannot change the design once you go through this stage.

- Depending on your target market:

- FCC (United States but accepted worldwide)

- CE (UK and EU but accepted worldwide)

- BIS (India)

- ATEX (fire safety)

- PTCRB (PTC Type Certification Review Board)

- WPC (Wireless Planning and coordination certification)

- Country specific certifications too.

- Ethically you should never cut corners here.

- Use your prototype to go through certifications.

Stage

Packaging

Your PCB and your 3D printed model work great with each other. But when you find out the costs for scaling up production you understand that the cost is very high. So your PCB as well as your mechanical designs need to go through a process called Design for manufacturability.- Examine the design to find out the ease of manufacturability index as well as the cost of manufacturability of each mechanical part.

- Redo the same for each electrical part after examining the cost of the bill of material of the PCB, the cost of the PCB itself etc.

- You may want to invest in making the mechanical mould at this stage.

Let us help you with your design for manufacturability. Schedule a time to talk to us.

Learn more about ambimat electronics